- Introduction

Introduction

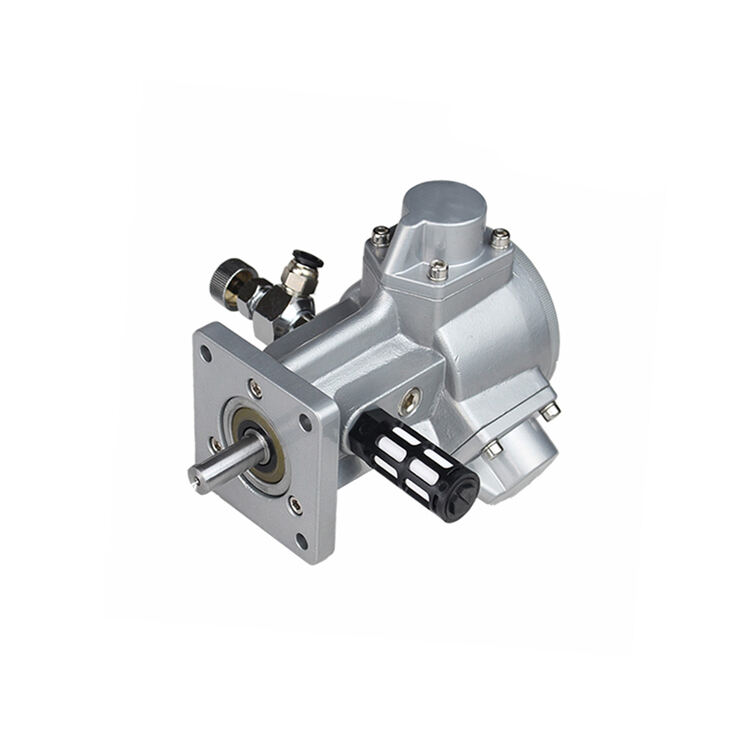

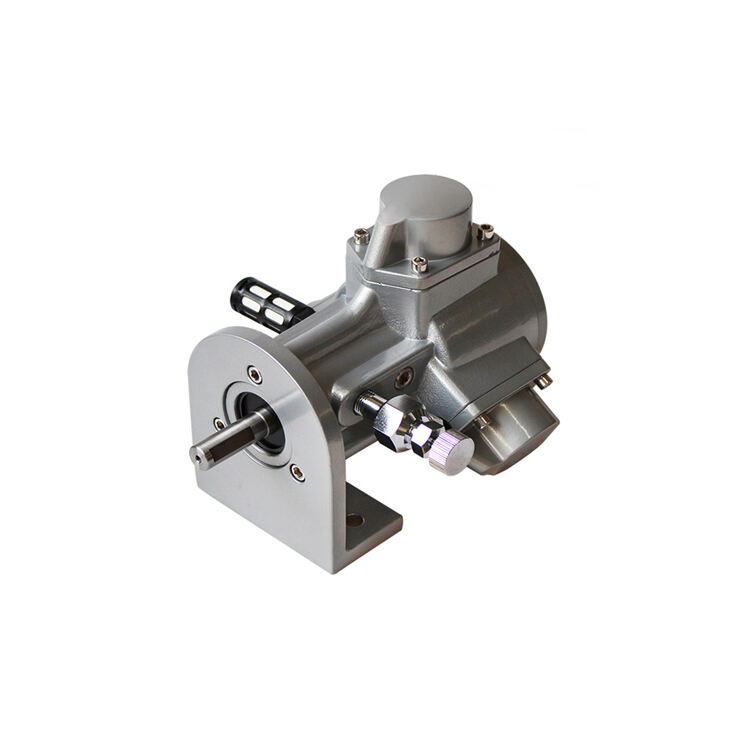

With compressed air as actuating medium, piston air motor converts the pressure energy of compressed air into rotary mechanical energy.

Compared to vane air motor, it has larger size and weight, lower speed, and more complex structure as per power unit, but has high started torque, well performance in low speed and longer service life.

| Motor Model | HXHM2-IEC140-S11 |

| Motor Power | 1/6hp |

| Speed | 1000rpm |

| Torque | 0.84N·m |

| Free Speed | 2000rpm |

| Direction of Rotation | Reversible |

| Air Pressure | 0.69MPa |

| Air Consumption | 211L/min |

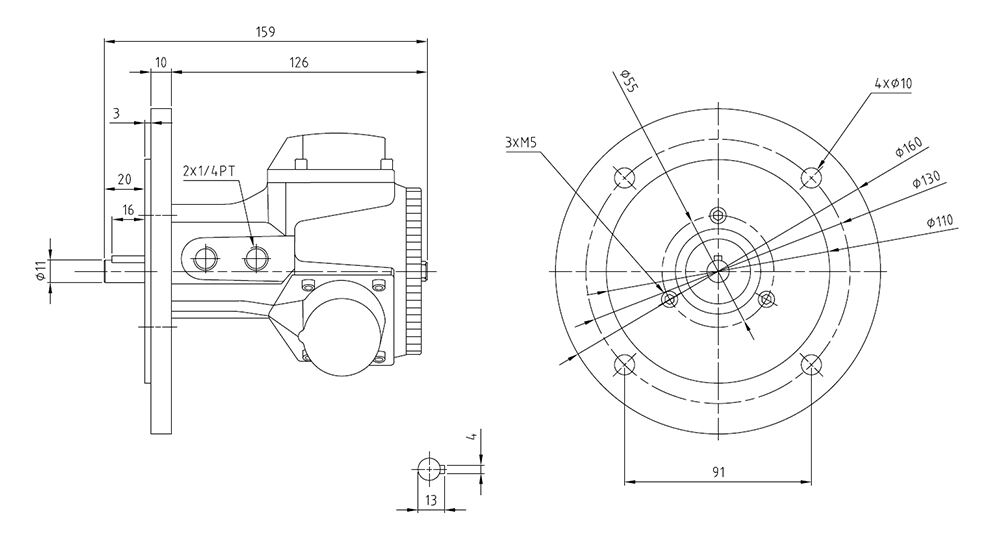

| Port Size | Air Inlet: PT 1/4" Air Outlet: PT 1/4" |

| Hose Diameter | I.D.=6.5mm |

| Shaft Diameter | 11mm |

| Housing Material | Die-casting Aluminium |

| Mounting Type | Flange Mounting |

| Weight | 2kg |

Notes

①Install an automatic air line lubricator in the air line within 18 inches (0.5 meter) or as close as possible to the air motor. The lubricator needs to be installed upstream of the air motor so that the oil mist will be blown directly into the motor. Make sure the lubricator is always filled with oil.

②Before connecting to the ports, clean the compressed air connections with low pressure air to remove any dirt or debris.

③Always use air lines that are the same size, or larger, than the air motor inlet port (refer to port size in the specifications chart).

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

TR

TR

MN

MN