- Introduction

Introduction

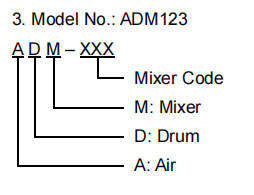

The air mixer ADM123 is mainly composed of a vane air motor, a connection set, a coupling, a stirring shaftand a folding impeller. It is designed for 250L (55 gallon) closed head steel drums. The mixer can be fixed on the drum by screwinginto the 2” bung opening. The folding impeller collapses to allow entry through 2” bung and opens when operating to providethorough mixing. The unit can be conveniently moved from one container to another. The speed of the air mixer can be adjusted bythe air inflow to meet the requirements of different working conditions. The air mixer is widely used for stirring chemical solutionssuch as ink, oil, glue, paint, etc.

| Mixer Model | ADM123 |

| Motor Model | HX4AM-F114.3-15 |

| Motor Power | 1.3 kW |

| Motor Material | Cast Iron |

| Max. Speed | 3000 rpm |

| Recommended Speed | 500-2000 rpm |

| 316L Shaft Size | Φ15.88×813 mm |

| 316L Impeller Diameter | 3.75 inches |

| Impeller Type | Folding Type |

| Number of Impellers | 1 |

| Port Size | 1/4" NPT |

| Hose Diameter | O.D.=10 mm | I.D.=6.5 mm |

| Air Pressure | 0.4-0.8 MPa |

| Max. Air Consumption | 2200 L/min |

| Mounting Type | Vertical Type |

| Weight | 13 kg |

| Viscosity | <500 cP |

| Mixing Capacity | 250 litres |

Notes

1. Install an automatic air line lubricator in the air line within 18 inches (0.5 meter) or as close as possible to the air motor. The lubricator needs to be installed upstream of the air motor so that the oil mist will be blown directly into the motor. Make sure the lubricator is always filled with oil.

2. Before connecting to the ports, clean the compressed air connections with low pressure air to remove any dirt or debris.

3. Always use air lines that are the same size, or larger, than the air motor inlet port(refer to port size in the specifications chart).

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

ID

ID

TH

TH

TR

TR

MN

MN